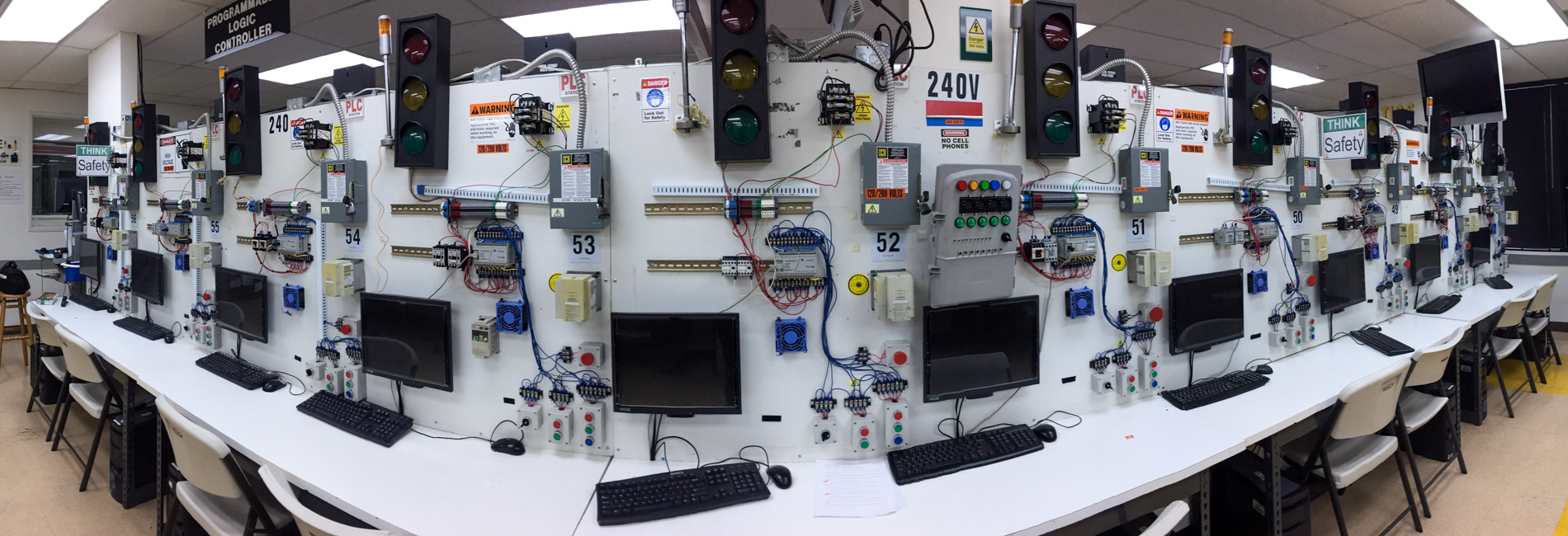

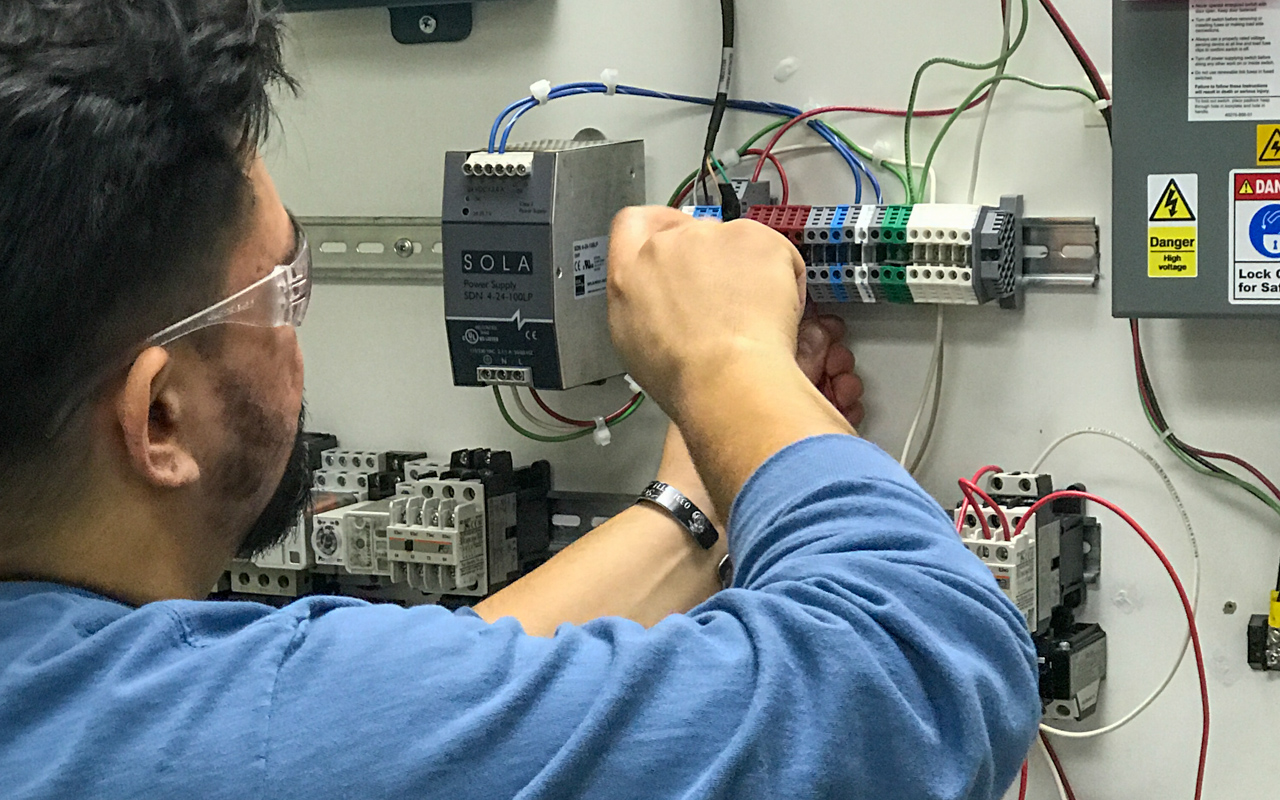

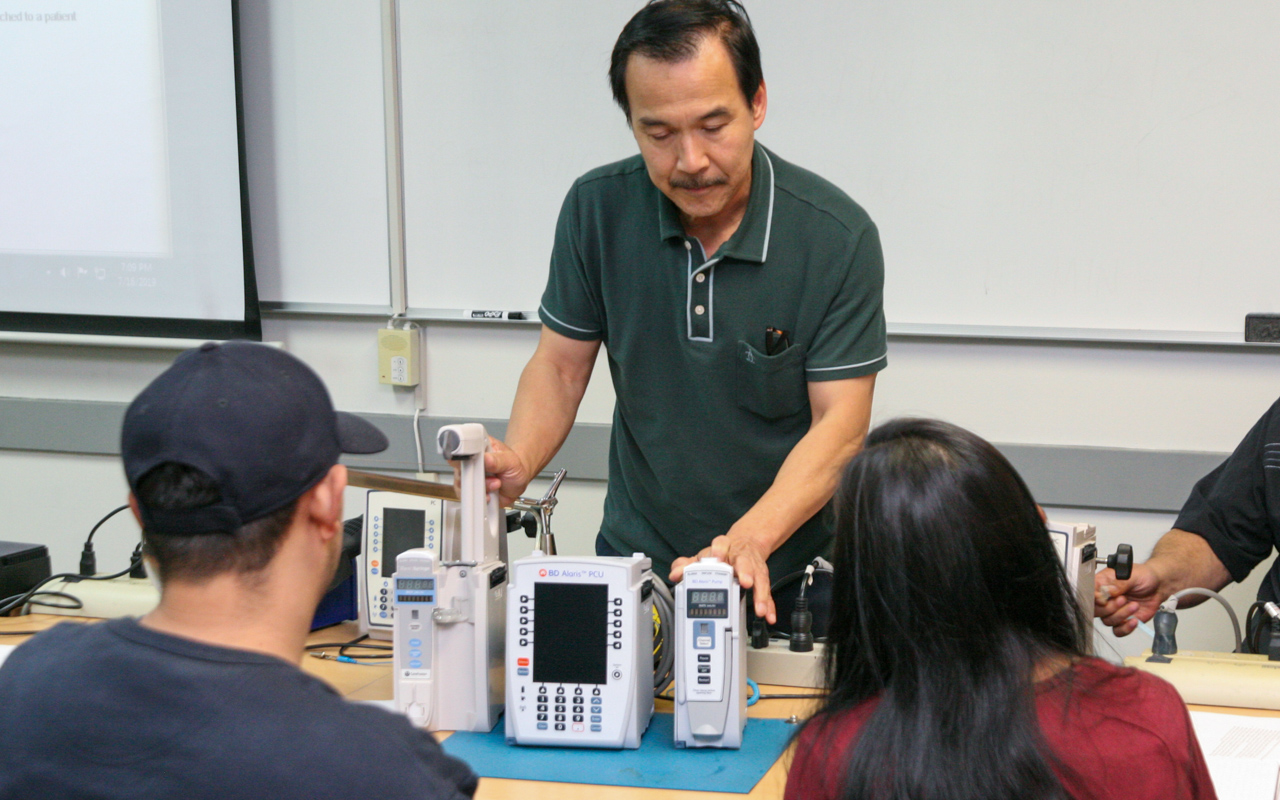

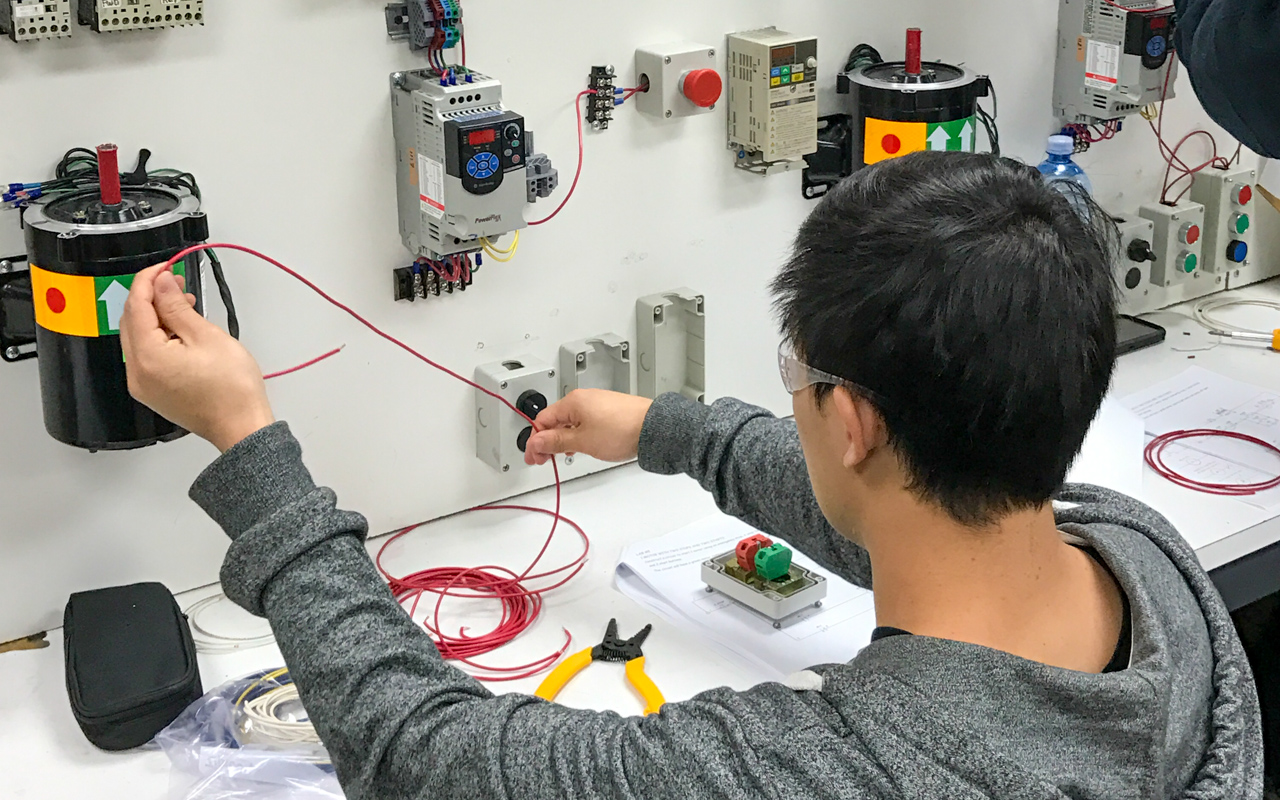

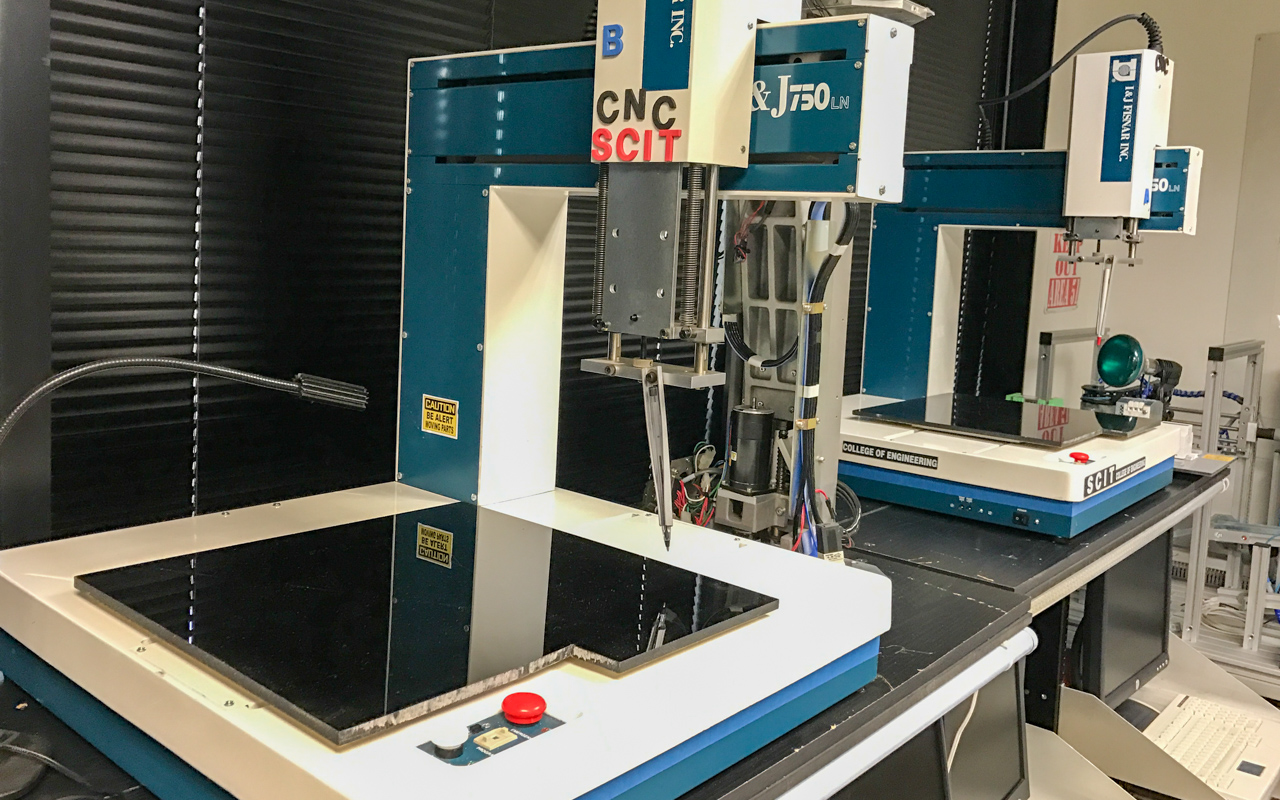

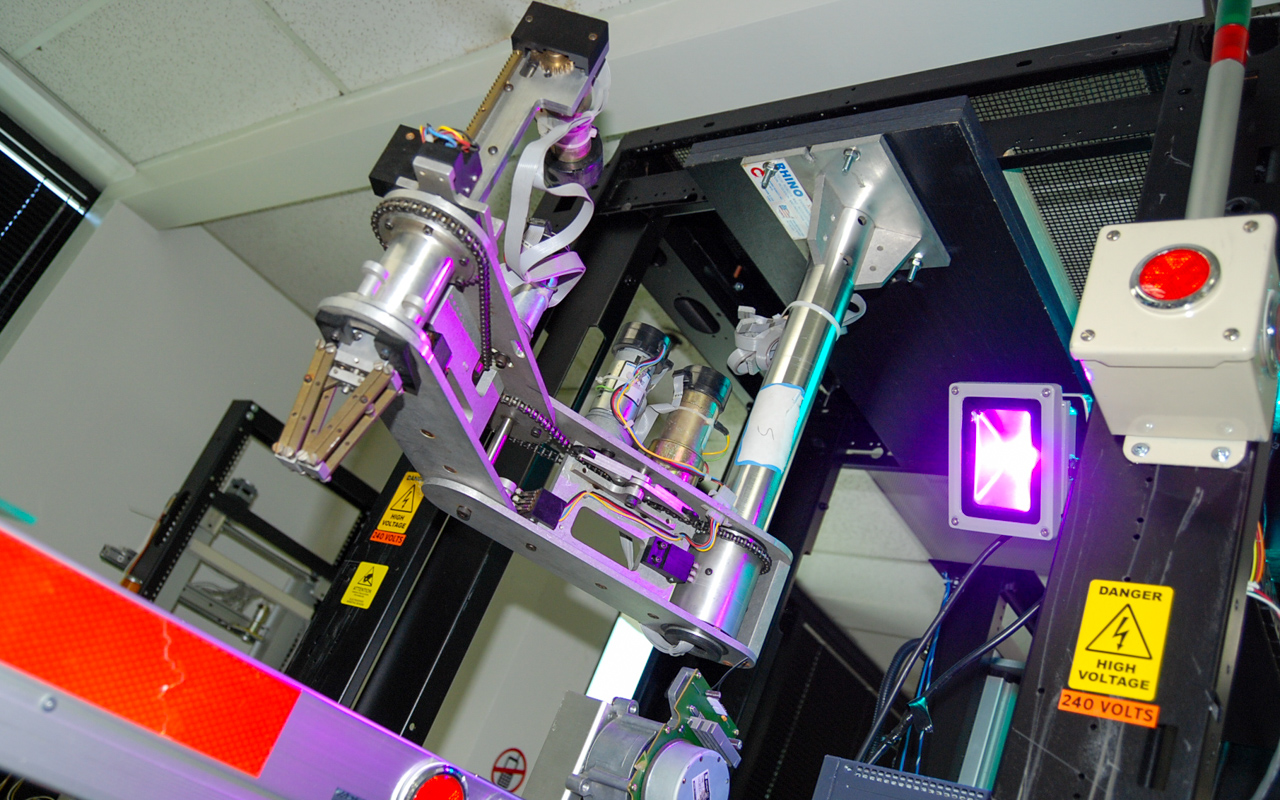

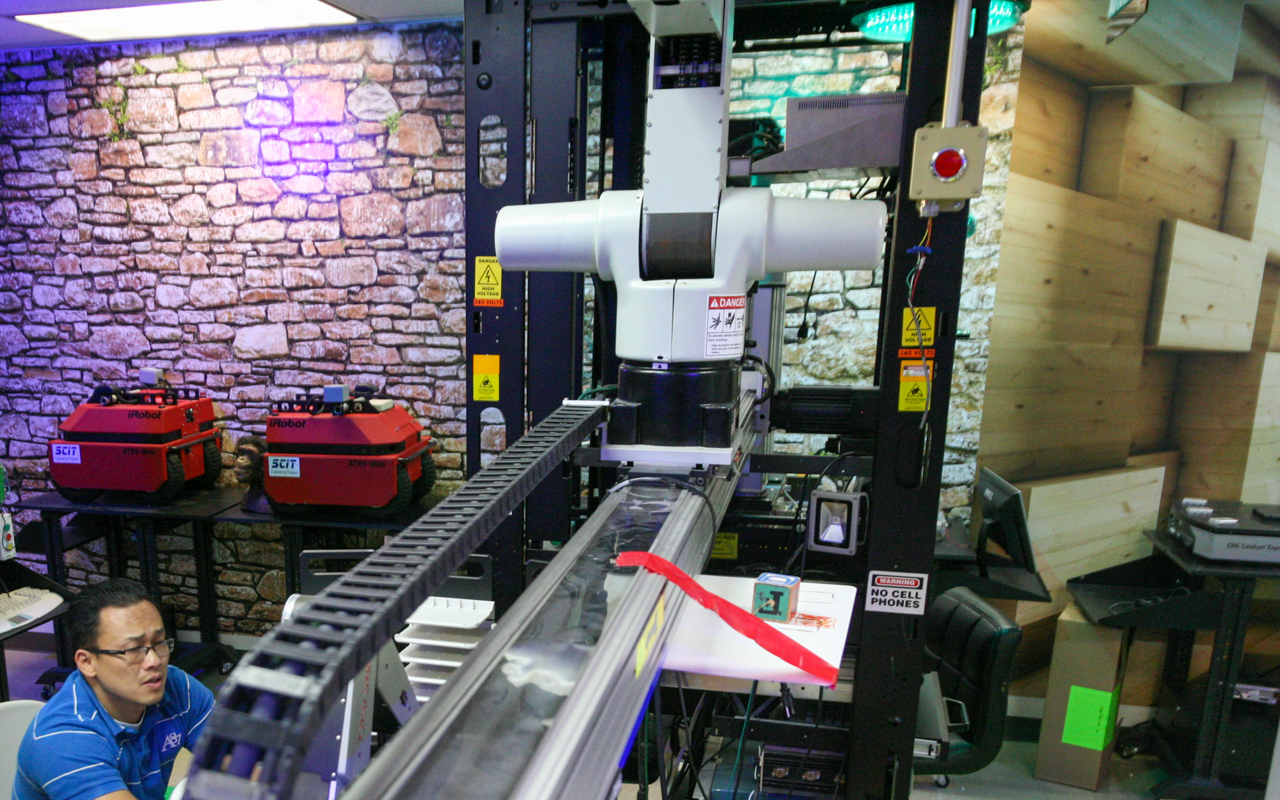

Hands-On Labs

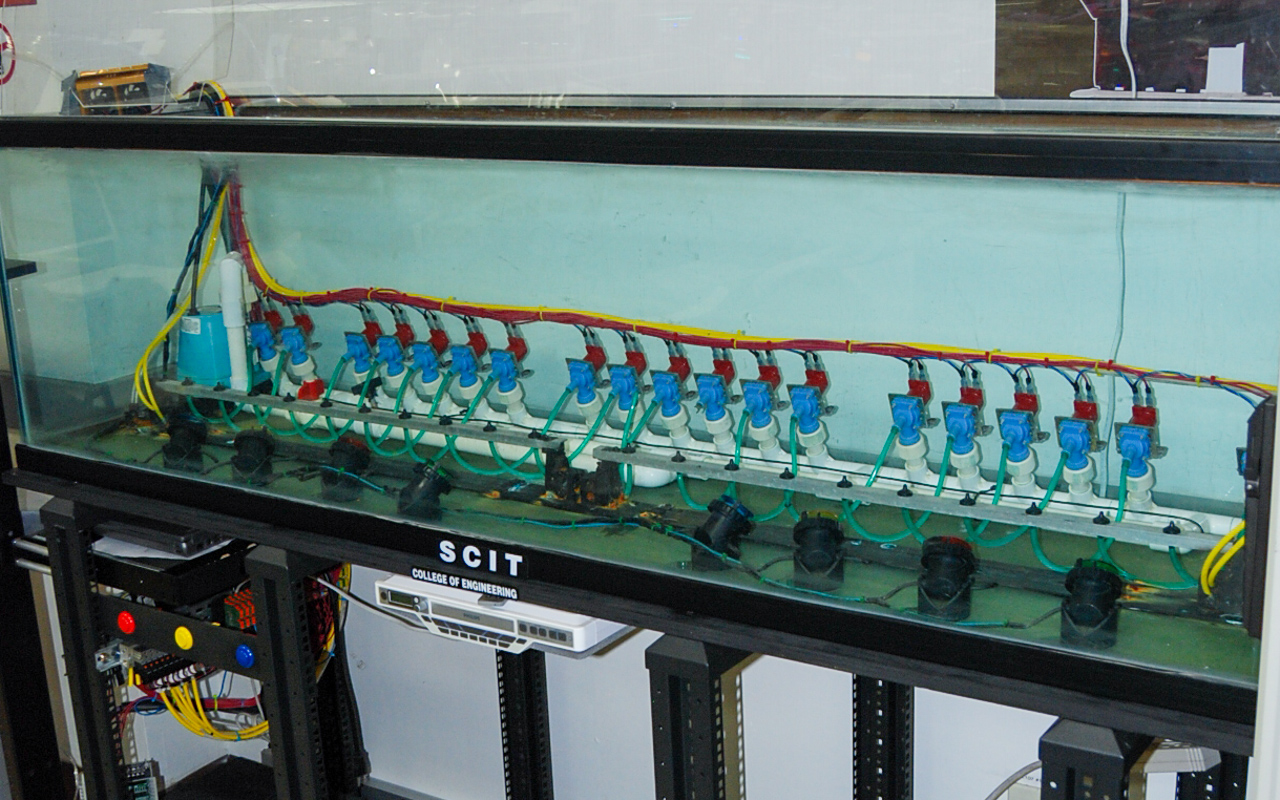

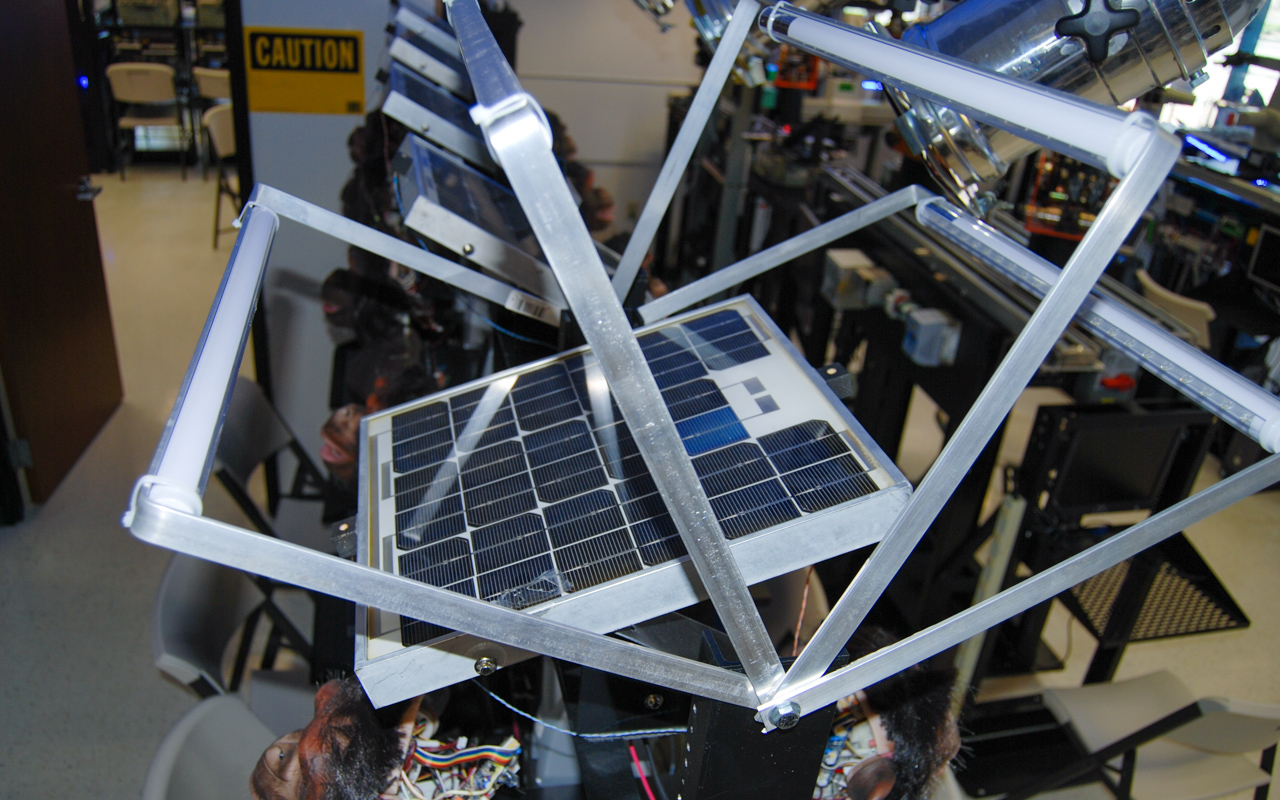

Explore SCIT Lab Spaces & Devices

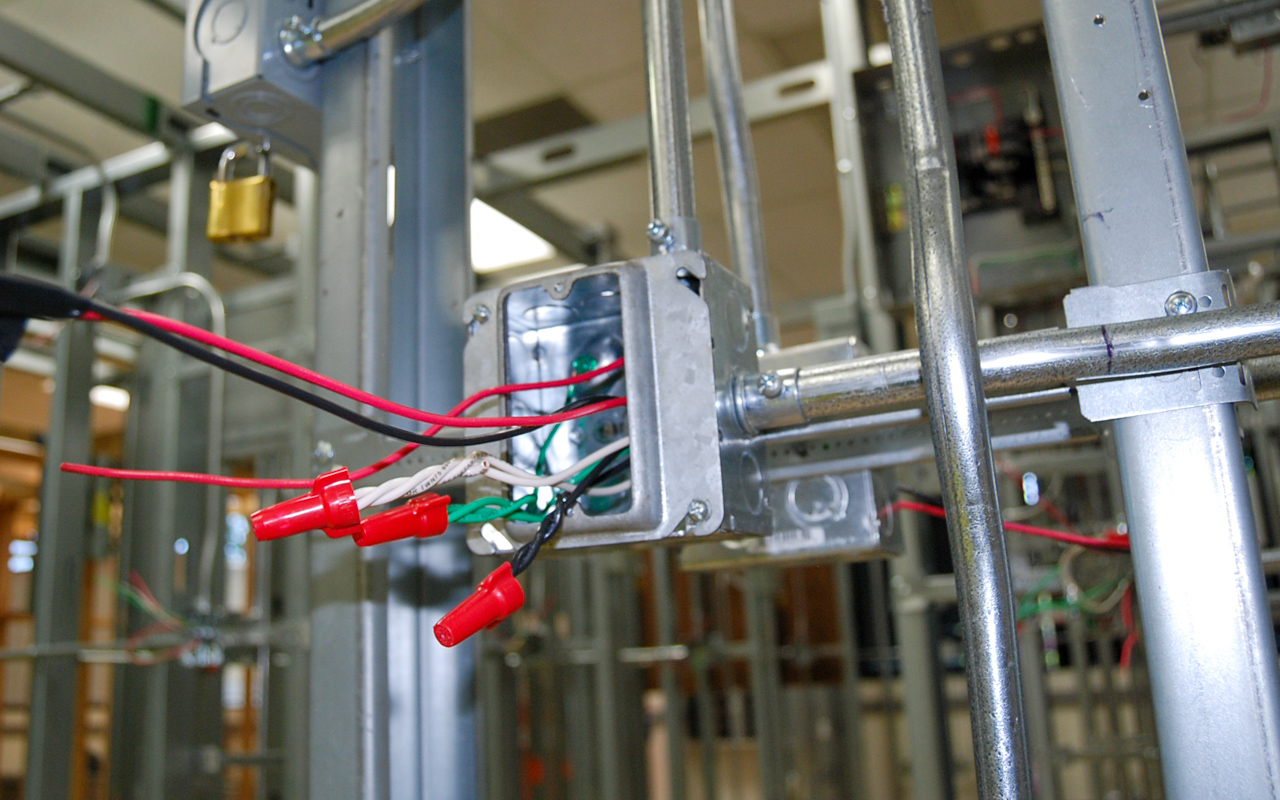

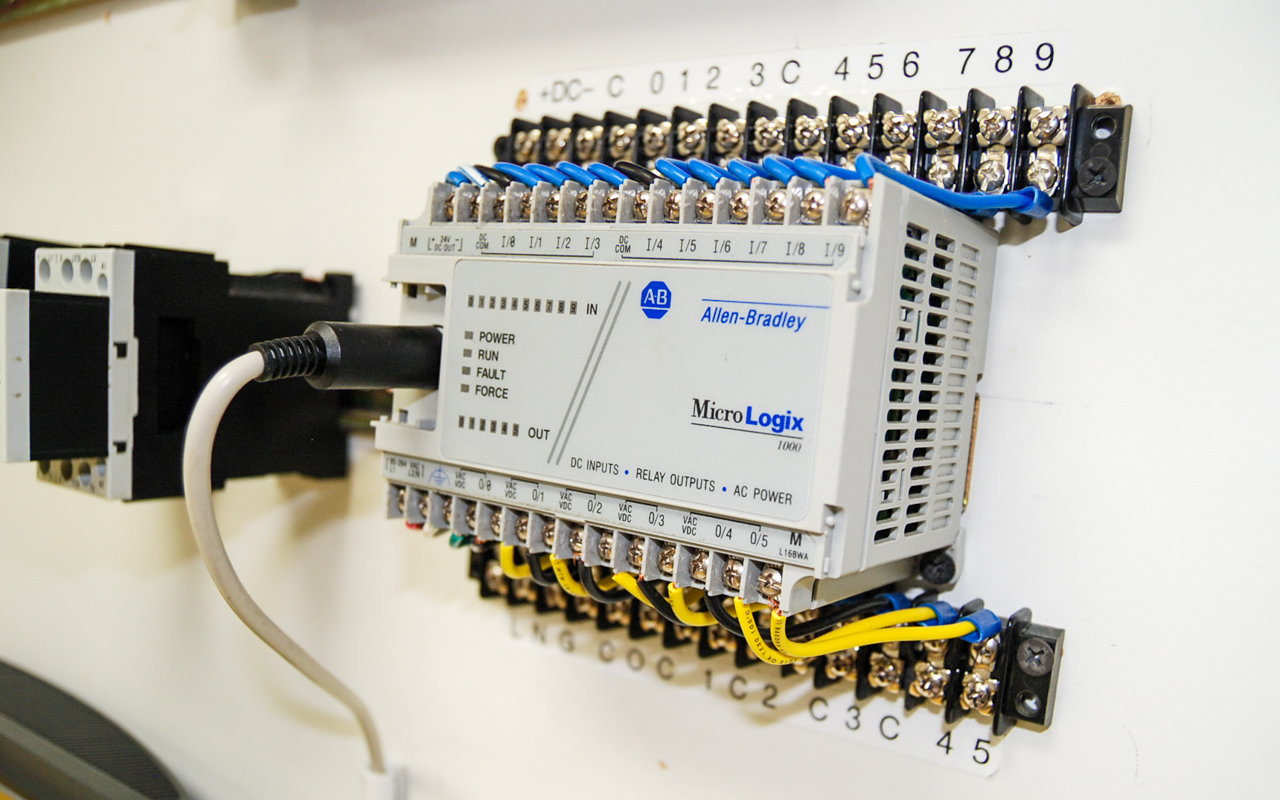

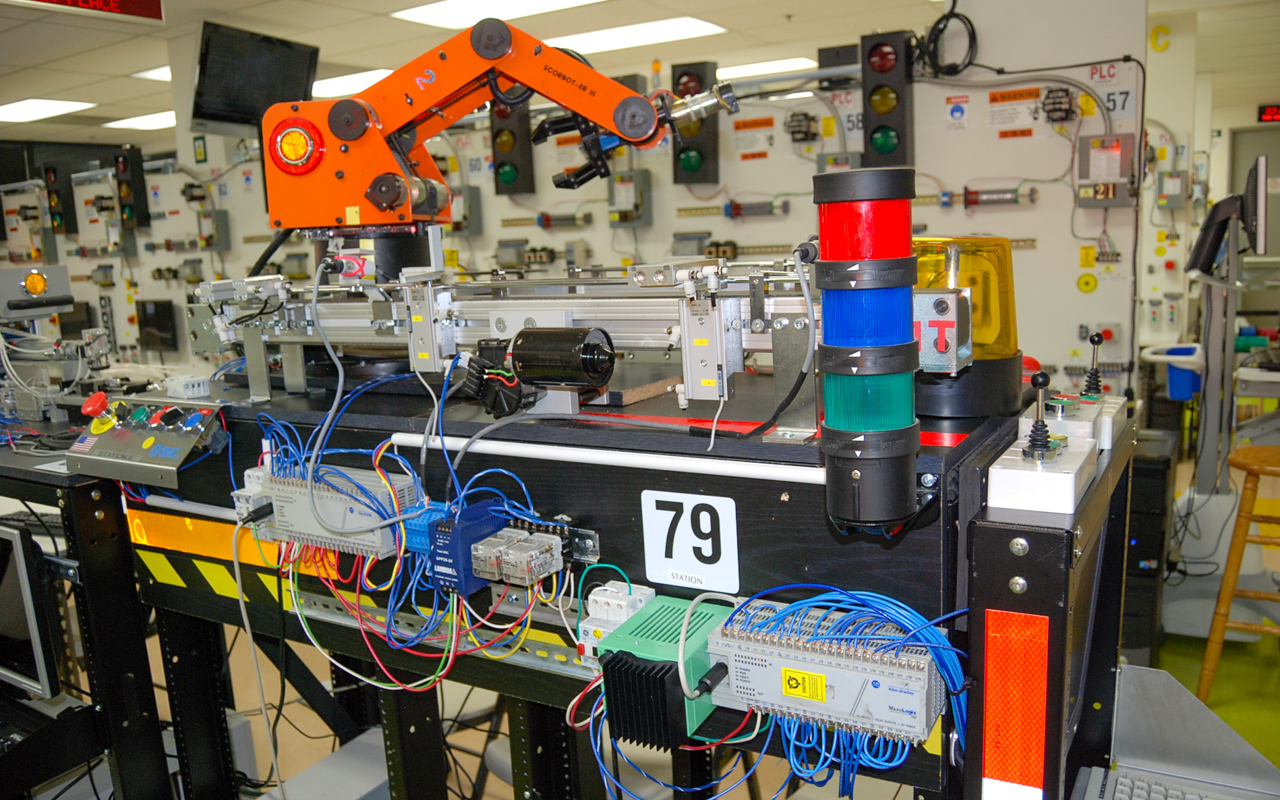

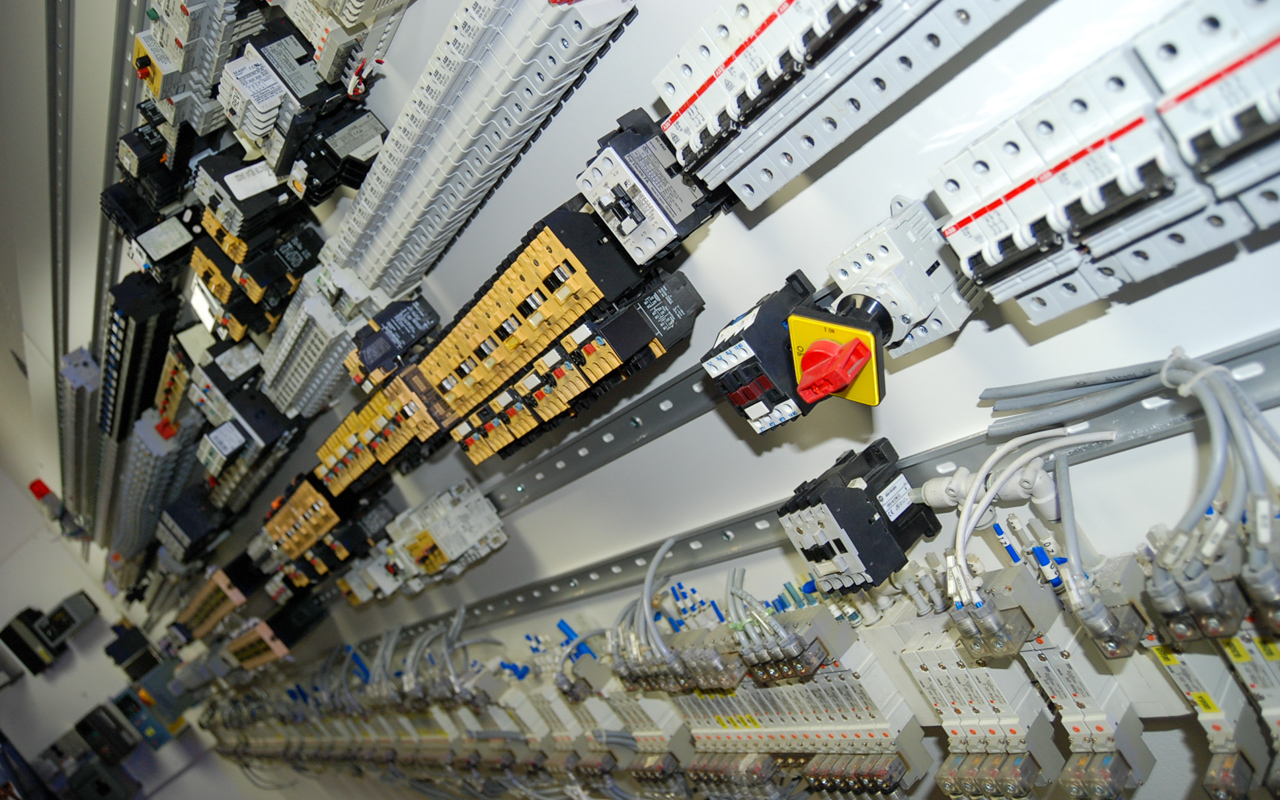

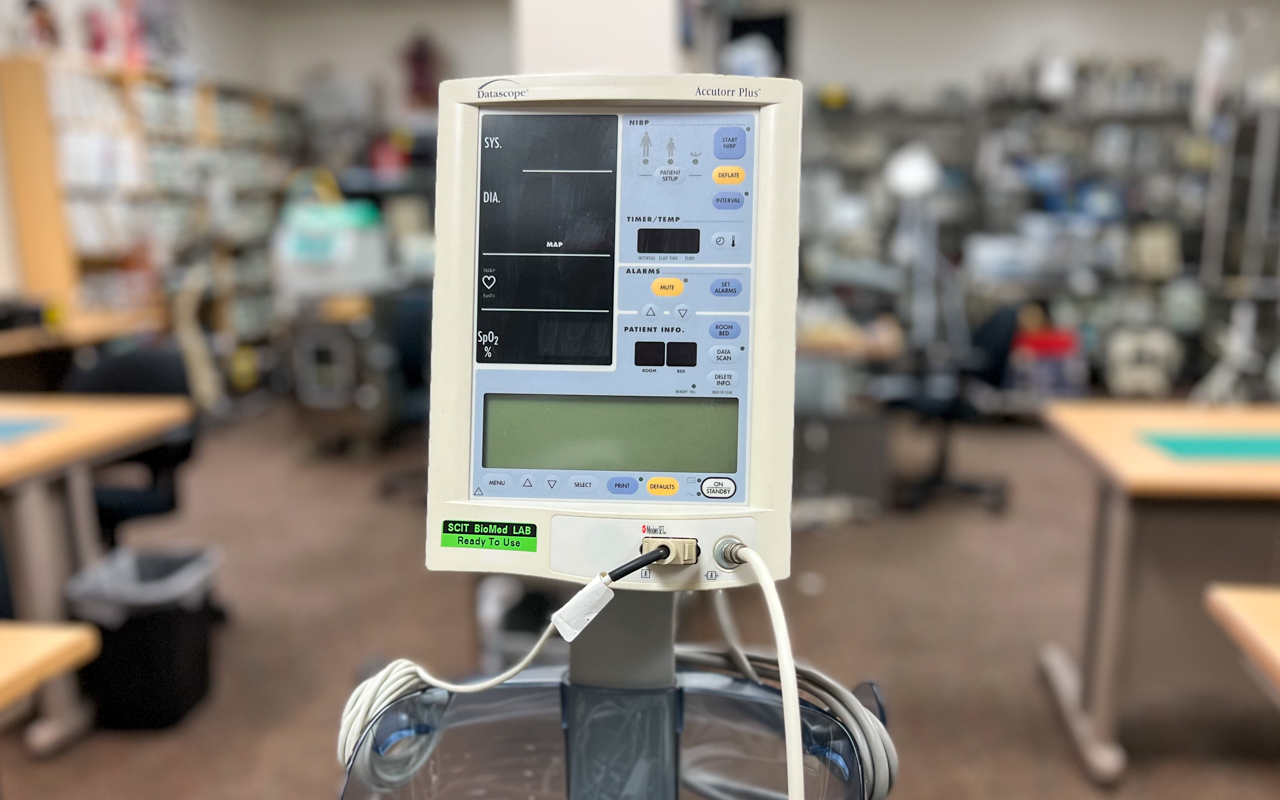

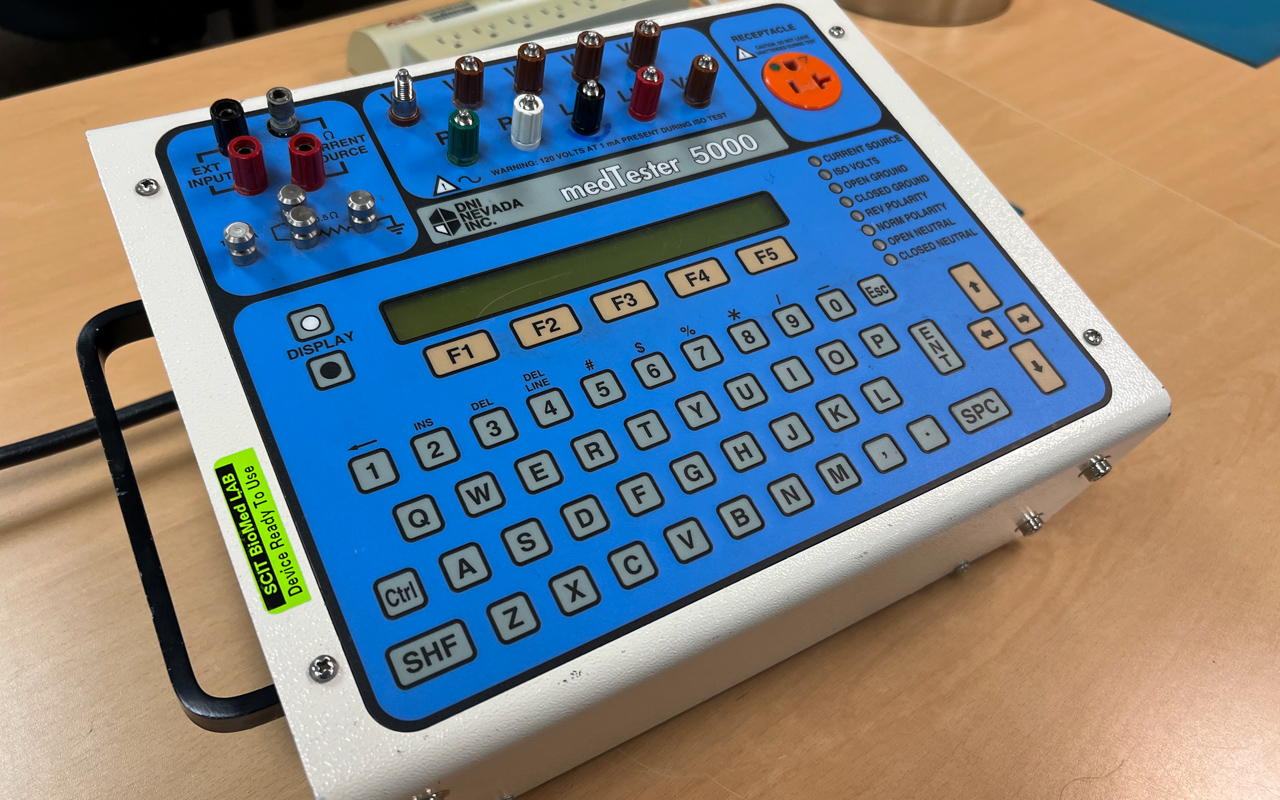

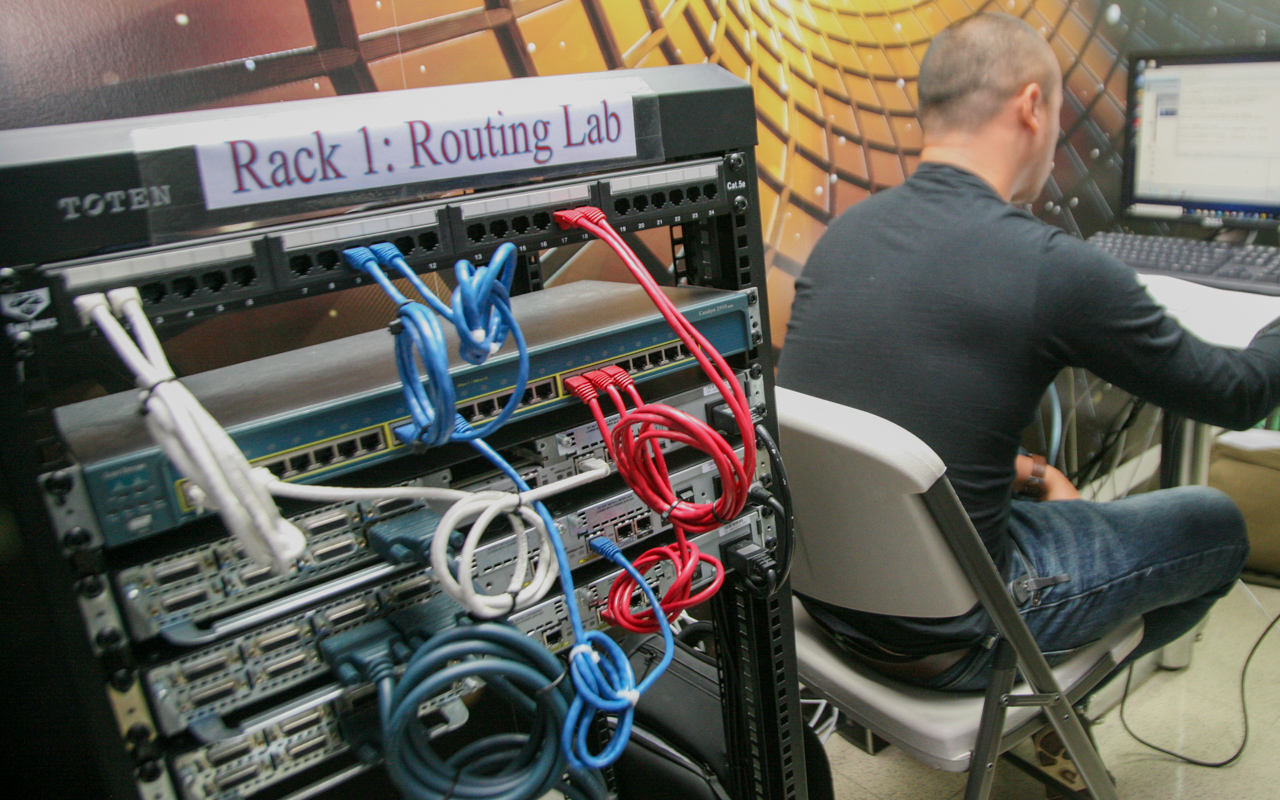

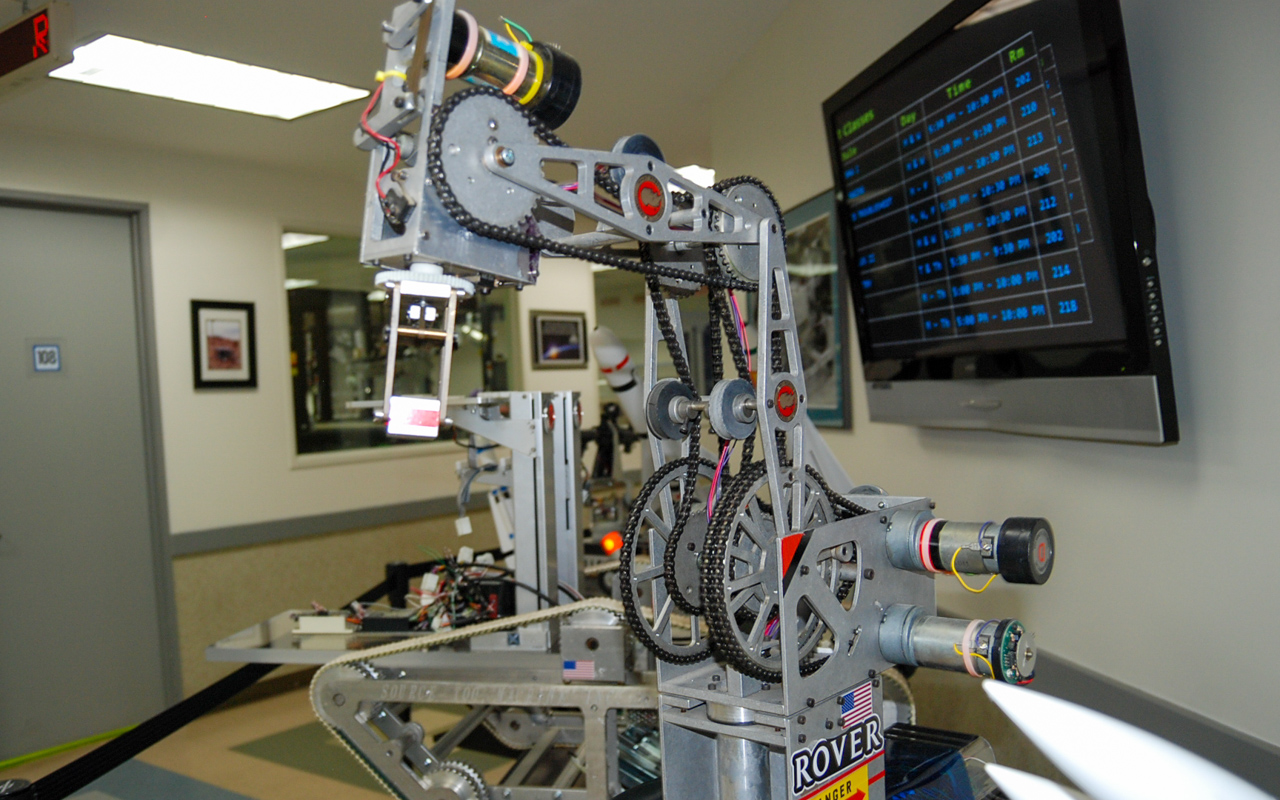

Labs are central to SCIT's mission. We design and develop lab spaces bringing together a range of industrial devices to afford students the opportunity to apply their knowledge.

Hands-Online: Prefer online programs? We have taken our labs and packed them into SCIT designed trainers that are shipped straight to your home. Learn more.

Laptop included in most programs*

Contact Admissions for more details

Software Applications

Employers are demanding more software knowledge

Engineers use software for a variety of applications from developing code that controls robotic systems to performing computational analysis on electrical signals. The ability to use an assortment of software is critical for career growth in technical fields. SCIT’s programs and labs teach and utilize some of the most popular software applications used by engineers and information systems professionals. Laptops and academic software licenses are provided to students as part of their program*.

*Laptops are not provided to students for programs that do not require them. Please contact the Admissions Office for more information.

MatLAB®

LabVIEW™

PSpice®

AutoCAD®

SOLIDWORKS®

RobotStudio®

C++

Windows Server®

AND MORE...

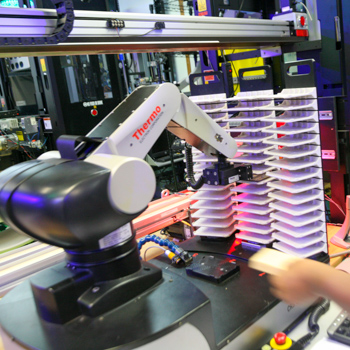

Trainers & Remote Labs

Learn hands-on in the comfort of your home

Students enrolling in online programs are shipped trainers to work on lab projects at home. SCIT designs and builds its own patent pending trainers to deliver the hands-on learning experience for students seeking more flexibility. For devices that are too large to ship (like 1000 pound robots), students can connect to SCIT’s lab facilities and remotely perform their lab projects with guidance from lab instructors.

Visit

The SCIT Campus!

Meet our staff and faculty,

tour our classrooms and labs, and

learn about our programs.

Call, email or request info to schedule.

CALL ADMISSIONS

SEND AN EMAIL

BOOK AN APPOINTMENT

Visitation appointments are usually made on Mondays-Fridays, between 10am and 5pm (except holidays).