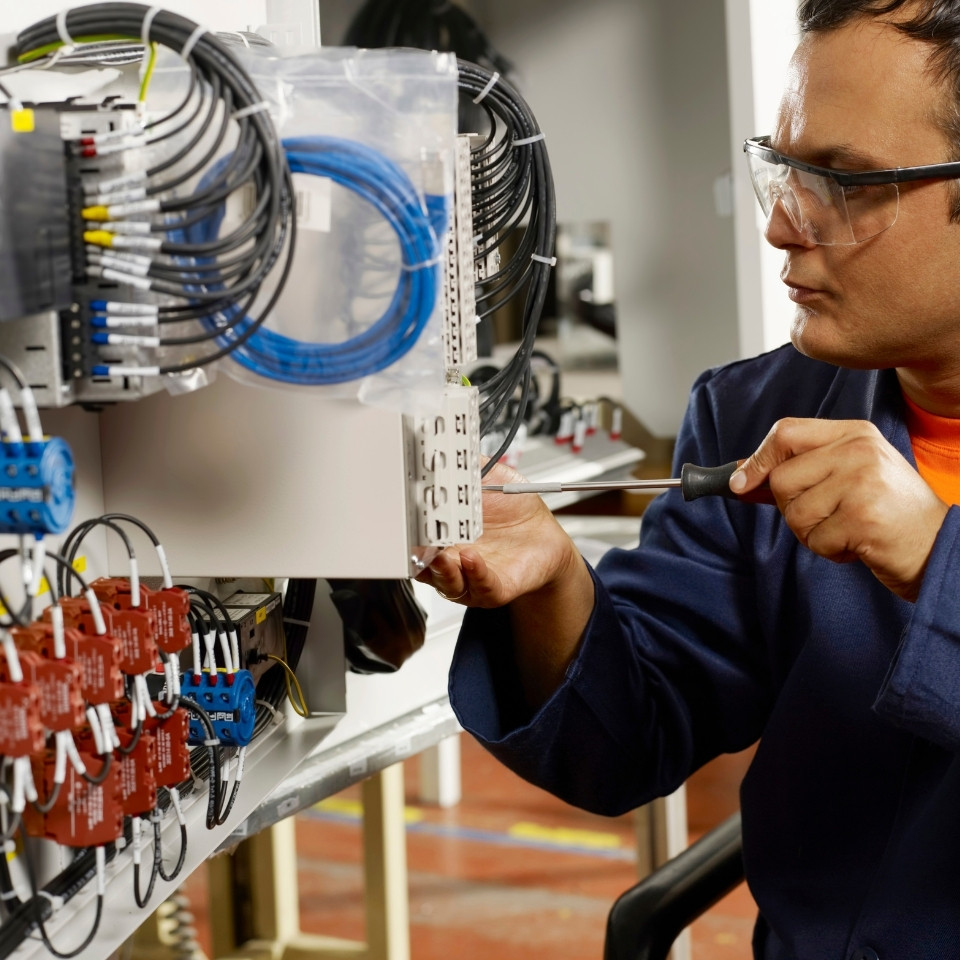

Learn to install, troubleshoot and program industrial devices used in automation systems in an 8 month, hands-on program aimed at preparing you for a range of industrial technician related professions.

8 Months

PM Classes

On-Campus

Request More Info

Submit form for more program information.

We Respect Your Privacy. Information submitted on this form is sent to the SCIT Admissions Department and is not shared with any third parties.

Request More Info

Submit form for more program information.

We Respect Your Privacy

Information submitted on this form is sent to the SCIT Admissions Department and is not shared with any third parties.

Key Program

TOPICS

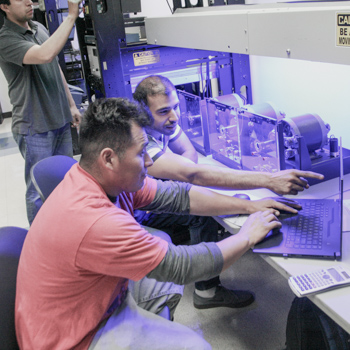

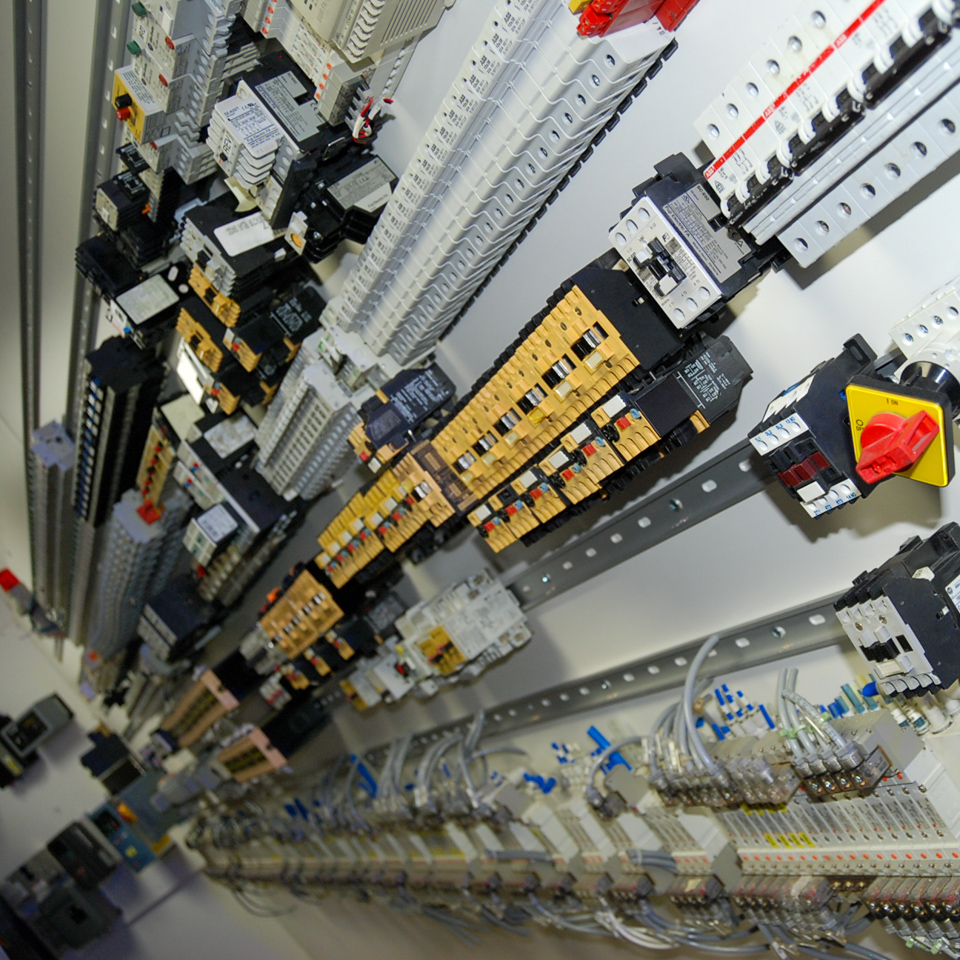

Learn by working hands-on with real industrial devices including different types of electric motors, PLC5000 control units, pneumatic devices, hydraulics, and much more. Explore key topics below:

Learn how to read and interpret the National Electrical Code (NEC) as it relates to basic electrical installation.

Learn how hydraulic and pneumatic devices are used in conjunction with control systems such as PLC’s to support automated processes.

Study advanced electric motor control concepts including modeling and parameter identification of SMPM machines, fully-controlled bridge converters, modulation techniques, voltage and current regulation, control of SMPM drives, variable frequency drives (VFD), synchronous motor drives, volt/hertz induction motor drives, indirect and direct field orientation control and optimal control of induction motor drives.

Train with advanced PLC5000 units to study such subjects as debugging ControlLogix and CompactLogix (5000), network technologies applicable to PLCs, debugging and diagnosing and PLC over TCP/IP, reading analog inputs, PID loops, and blueprint reading for automation.

B.S. Electrical Engineering Degree Opportunities

Students may have the opportunity to continue their education toward a degree to open further career opportunities.

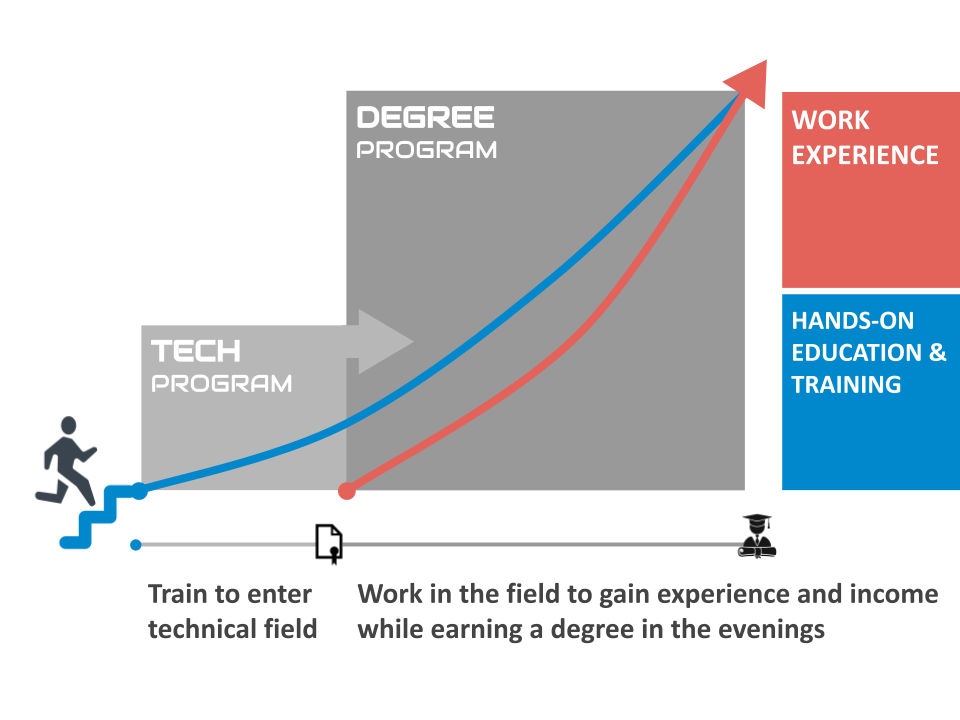

Electrical Career Pathway

Start by completing the Industrial Automation Technology program and find entry level employment in the electrical field. Work in the field while pursuing a B.S. Electrical Engineering degree in the evenings. At the end you will have a diploma, a degree and work experience.

Learn more about BSEE program.

Degree Topics Include: Digital Electronics, Semiconductors and Circuits, Programming, MATLAB, Signal Analysis, Computer Aided Drafting (CAD), 3D Modeling with SolidWorks, Embedded Systems, Robotic Engineering, Control Systems, Electric Machines, Power Systems, Power Distribution, Power Protection, Senior Capstone Project and much more.

Support to Reach Your Goals

The Student Services and Career Services Offices support you on your educational path to greater career opportunities.

Academic Support: Advisement, academic monitoring, tutoring, and more...

Career Support: Resume assistance, career workshops, job leads, and more...

Visit

The SCIT Campus!

Meet our staff and faculty,

tour our classrooms and labs, and

learn about our programs.

Call, email or request info to schedule.

CALL ADMISSIONS

SEND AN EMAIL

BOOK AN APPOINTMENT

Visitation appointments are usually made on Mondays-Fridays, between 10am and 5pm (except holidays).